Construction 4.0 - Digital revolution in construction business

As a result of the new corona-virus, construction investments have been slowing down, which will lead to declining revenues. In order to maintain work and security, more and more people are forced to work from home. Home office gives us the opportunity to pause for a moment and think about how we can work more effectively. The impact of the pandemic highlights the fact that the construction industry is particularly sensitive to the presence of labour. Today, every generation is forced to learn and take advantage of the opportunities offered by digital technology. The sudden slowdown in work provides a good opportunity to reflect on how well we are working in the construction industry. Have recent growing revenues resulted in the same level of profit growth for businesses in the industry?

If we consider the major technological changes that have taken place in the field of construction, we may experience that Hungary has been falling behind. The first major technological change was the transition from paper to 2D digital design. This was followed by the release of the Hungarian software called ArhiCAD, which brought a world-wide technological transformation and - according to numerous studies - created the possibility of BIM-based design.

How are BIM, technology, profit and efficiency related? What is the reason why few people feel the positive impact (increased efficiency and profit) of technology on the market?

Is it time to reflect on the cause of the problem? The market is changing and BIM assumes a completely new business model. It is not enough to integrate technology at the organizational level. Current project management processes need to be renewed at full project level. The benefits of using BIM technology from design to operation are realized when all stakeholders are involved in the process. For this to happen business executives need to understand that we are on the verge of a major technological transformation: Construction 4.0 has begun. A digital revolution has started in all parts of the world in the construction industry, with BIM as its foundation. Of course, besides BIM, many new technologies have emerged that can save significant resources.

Now is the time for businesses to rethink where they are headed. Do they want to increase efficiency with the right technology, or increase workforce and get stuck in the past? Have you ever considered developing a digital strategy? How will the new technologies be applied or what new technologies are there at all? Do they have sufficient skilled labor?

Developing a state-level strategy for the transformation of national construction technology could significantly support this transformation. For example, in Europe, the United Kingdom has set a national strategic goal for the digital transformation of the construction industry. This strategy is supported by ongoing research, for example at The Center of Digital Built Britain, which has a partnership with Cambridge University. In Estonia, the Digital Construction Cluster was established with governmental support, which also focuses on technological changes in the construction industry.

What is the Future of the Construction Industry? What does Construction 4.0 mean? What emerging technologies will help the construction industry in the future in design, construction, inspection, safety and raw materials? The Construction 4.0 conference in Israel in February presented a particularly interesting and useful direction in technology.

Construction 4.0 – Conference report

In recent years, Israel has become the center of technology and innovation in the construction innovation. Continuous innovations made it possible for the first time this year for the city of Tel Aviv to host the Construction 4.0 International Conference on February 26, 2020. Nearly 300 international participants, start-ups, market leaders, international experts and multinational companies were introduced in the topic of Construction Industry digitalisation.

The conference was organised by the ConTech Construction Innovation Zone. This society was created by Zachi Flatto three years ago. His vision was that Israel should become a market leader in construction technologies through start-up generations and innovative technologie. Through their program, their activities are aimed to grow the construction tech start-up ecosystem, while facilitating business connections between start-ups and industry players in Israel and abroad. The basis of their operation is not only the vision created by the organization; but the national strategic goal which includes sustainable development and market opportunities set by the Israeli Ministry of Economy and Industry and the Ministry of Housing and Construction.

During the opening notes the common vision was confirmed by Raul Srugo (President of the Israeli Builders' Association), Moran Buganim Gold, Director of Israel Newtech & Ecosystem, Ministry of Economy and Industry), Netaniel Lapidot (Deputy Director General for Strategy and Policy Planning, Ministry of Housing and Construction); and Karin Gattegno (VP of Strategic Partnerships, Start-Up Nation Central).

The main purpose of the event was to present the emerging start-up ecosystem to the construction industry. The presentations were grouped into three main topics: Artificial Intelligence, Robots, and 3D Printing.

Construction 4.0 Market Overview and the Future

„Today we are still very early in the stage of Property Technology investing. We are far under 1% at Venture Capital invested in assets globally in the Real Estate. In other sectors it is about 3%-7%.”

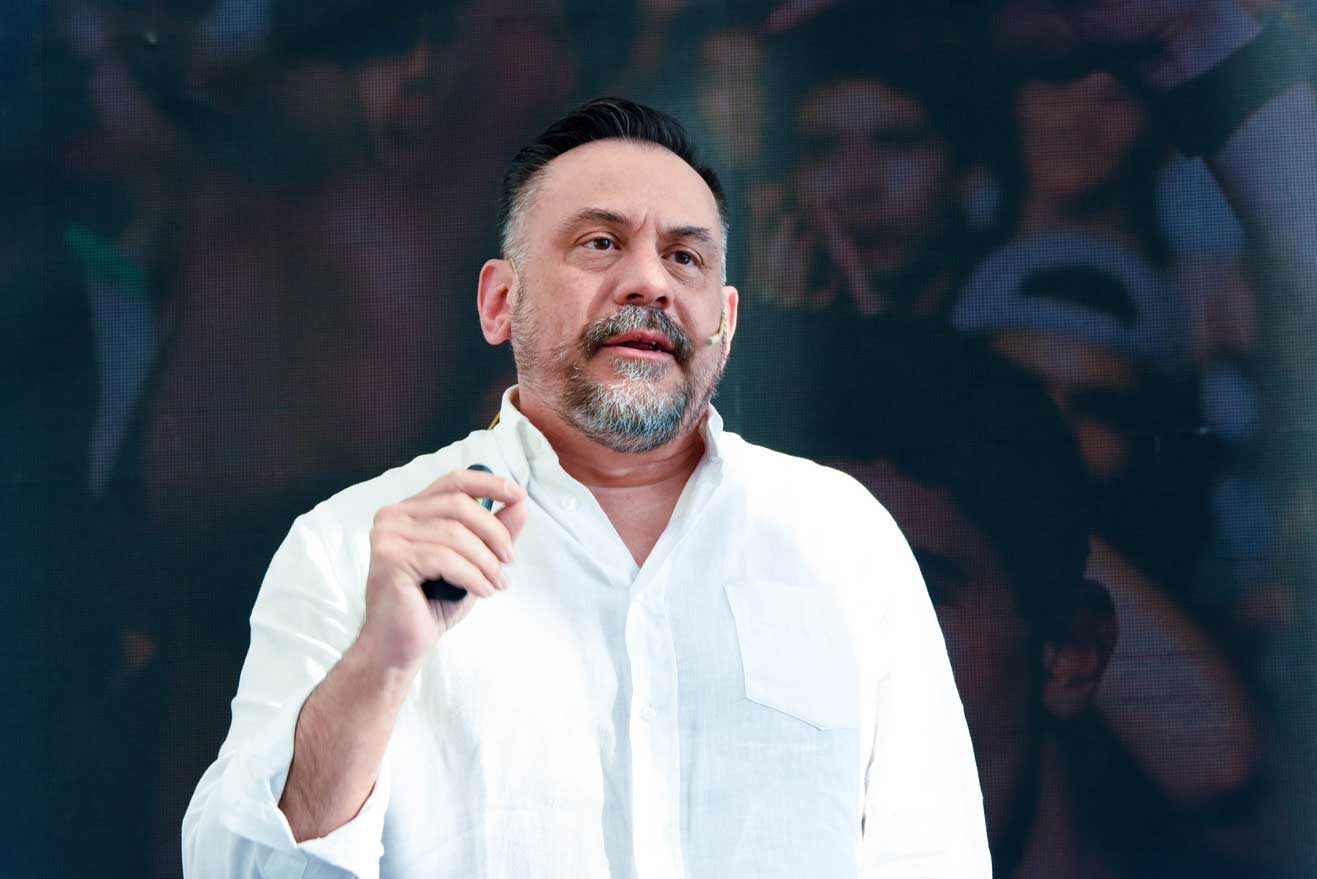

The first keynote presentation of the conference was given by Leonard Brody, who is also a co-founder and chairman of Creative Labs. In his speech, he explained - through the New York example of the Second Industrial Revolution - that false historical biases had caused failure for most businesses: while in the 1900s we could see only one car on the streets of Fifth Avenue, 13 years later there was only one horse-drawn carriage on the street. The construction technology market potential was illustrated through this example. The digital transformation of the construction industry has been started, it is needed to be considered that this transformation is going to happen very fast.

From Idea to Building – Innovation Process in Digital Design at Arup

“The whole design process is shifting in different directions. The workload is shifting in different parts of the design process, because a lot of the things you have to do much earlier now than you would have done in the past"

Rudi Scheurman, Arup's Global Director and Fellow, demonstrated the process of innovation through the construction of the 2006 FIFA World Cup sculptures. Each sculpture represented the country's history and innovations; it symbolised the rich and inventive society of German scientists and engineers; so, it was a priority project for the company. These sculptures included the theory of relativity, the automotive industry, modern printing, or statues featuring musical masterpieces.

Arup has completed the Walk of Ideas project over a 3-month period, during which was involved in building materials consultancy, structural engineering and facade design. After great research, the company has developed a concept for a completely innovative building material. 26 separate elements were made for each sculpture. Various shapes of each block were created by computer sculpting techniques, and the surface was reinforced with plastic and placed in 3D steel frames. This process was later adapted by the company's vehicle design team and other representatives of the automotive industry as the technology is an alternative to the bronze casting and manual modelling techniques traditionally used in statues of this size. Throughout the project, the entire construction process was optimised for each sculpture, resulting in a unique and cost-effective solution.

Construction 4.0 – Building a new world with AI and Robotics

“For the new industrial revolution in construction, we have to train robots to think like humans instead of humans thinking like robots.”

Tal Friedman's Construction 4.0 - Building a New World with Robots and Artificial Intelligence captivated the audience.

Foldstruct is using revolutionary technologies: they have created unique algorithms and robots to create forms from traditional industry materials that were previously impossible for the industry. Custom design and production technology allow developers to create iconic designs within minimal budgets. Foldstruct minimizes the amount of material used while creating energy efficient, thin shell structures. In the future, you won't need expensive shapes or endless amounts of unique components. State-of-the-art robotics and artificial intelligence make it possible to create new forms. Design is transforming in many areas, including construction, architecture and aerospace.

Panel – Construction for a Better World

Moderator: Bryan Lyandvert Investor, MetaProp; Prof. Yehiel Rosenfeld, Technion; Meirav Oren CEO, Versatile; Sven Harmsen, Director External Ventures, Nova Saint-Gobain; Jeremy Brown, Investor, Foundamental; Arch. Shany Barath, ShaGa studio; Guillaume Bazouin, Open Innovation & Startup Programs at Leonard, VINCI Group

A panel discussion was also a part of the conference where several experts were consulted on new construction technologies and how the market will change. Although opinions were mixed, there was one shared opinion by professionals: the change had begun, market transformation had begun, and a whole new digital construction market was born. The biggest challenge for the market is that the learning curve for the construction industry is not similar to any other industry. Processes are very slow and there is not enough experience to implement new technologies with a standard solution.

Lean Session – Modular Construction

Investors presented two market sectors for modular design: 3D printing and modular design.

Mateo Zimmermann from Cemex's Investor Business gave examples of the 3D printing market. He emphasized that the biggest challenge of prefabrication is integration and complexity. Creating standard elements and making them mass-produced.

Werner Bittner introduced Neulandt 3P (N3P). Neulandt GmbH is a subsidiary of Umdasch Group Ventures, which is also a construction innovation centre. Neulandt GmbH has improved a mobile precast plant. The Neulandt plant itself is packed up in 40 sea freight containers when transported to or between job sites. They produces walls or slabs no modules. However, these wall segments and slabs are mass produced at unbeaten productivity directly at the job site and for highly standardise mass housing in 4-6 weeks.

In addition, within the 3D printing, the following four technology segments were introduced:

1. 3D Construction Artwork

2. 3D material production

3. Printing 3D Shell Structures (25-35% of the Construction Market)

4. Contouring Crafting (printing and automation)

There are many factors that need to be taken into account in the four new emerging segments in order to make the start-ups viable. Considering the cost-time-quality triangle, new technologies must overcome traditional technologies. Mass production and large number of quantities should be considered in the construction industry. One of the major challenges is that standards and regulations are not yet available for these new technologies.

Lean Session - 3D Printing - The Trojan Horse Forcing the Digitalization of Construction

About the author

- Online business consulting, support and help in the growth strategy, support the potential challenges of the European market, help finding potential customers

- Digital Construction Strategy, help and support choosing the right technology for a specific problem, technology implementation strategy and technology implementation.