ESG in Construction: From Obligation to Opportunity

In recent years, the demand for compliance with sustainability goals and ESG criteria (Environmental, Social, and Governance) has become an integral part of the construction industry. It is no longer just something to tick off to please a regulator or developer, but a full-fledged management tool that brings real operational value: saving money, reducing risk, and improving the project's image.

Instead of thinking about sustainability as an added cost, more and more companies view it as an opportunity: to choose smart materials, reduce waste and carbon emissions, and build in a way that supports both the environment and the business outcome. New materials and technologies being introduced into construction sites today were developed specifically to help meet environmental and regulatory goals without inflating budgets or delaying schedules, and in some cases, even the opposite.

Materials that already deliver - both environmentally and economically

Some of the most interesting innovations in green construction today begin with the material itself. Entrepreneurs and researchers in Israel and around the world are developing smart solutions that integrate sustainability right at the stage of material selection, without compromising engineering performance, durability, or cost. These are not futuristic experiments, but materials already in use in real-world projects, changing the way we plan and build. Here are three particularly outstanding examples:

Criaterra: Tiles made from natural materials that reduce energy use and pollution

The Israeli company Criaterra develops tiles made of one hundred percent natural, recyclable, and even biodegradable components. Compared to regular ceramic tiles, Criaterra’s production process consumes only about five percent of the energy and emits less than one percent of the pollution. Unlike ceramics that are fired at high temperatures and lose their natural composition, Criaterra’s products preserve the original chemical structure of the materials, allowing them to return to the environment at the end of use. Criaterra’s products are entirely made in Israel and are certified with the Israeli Green Label.

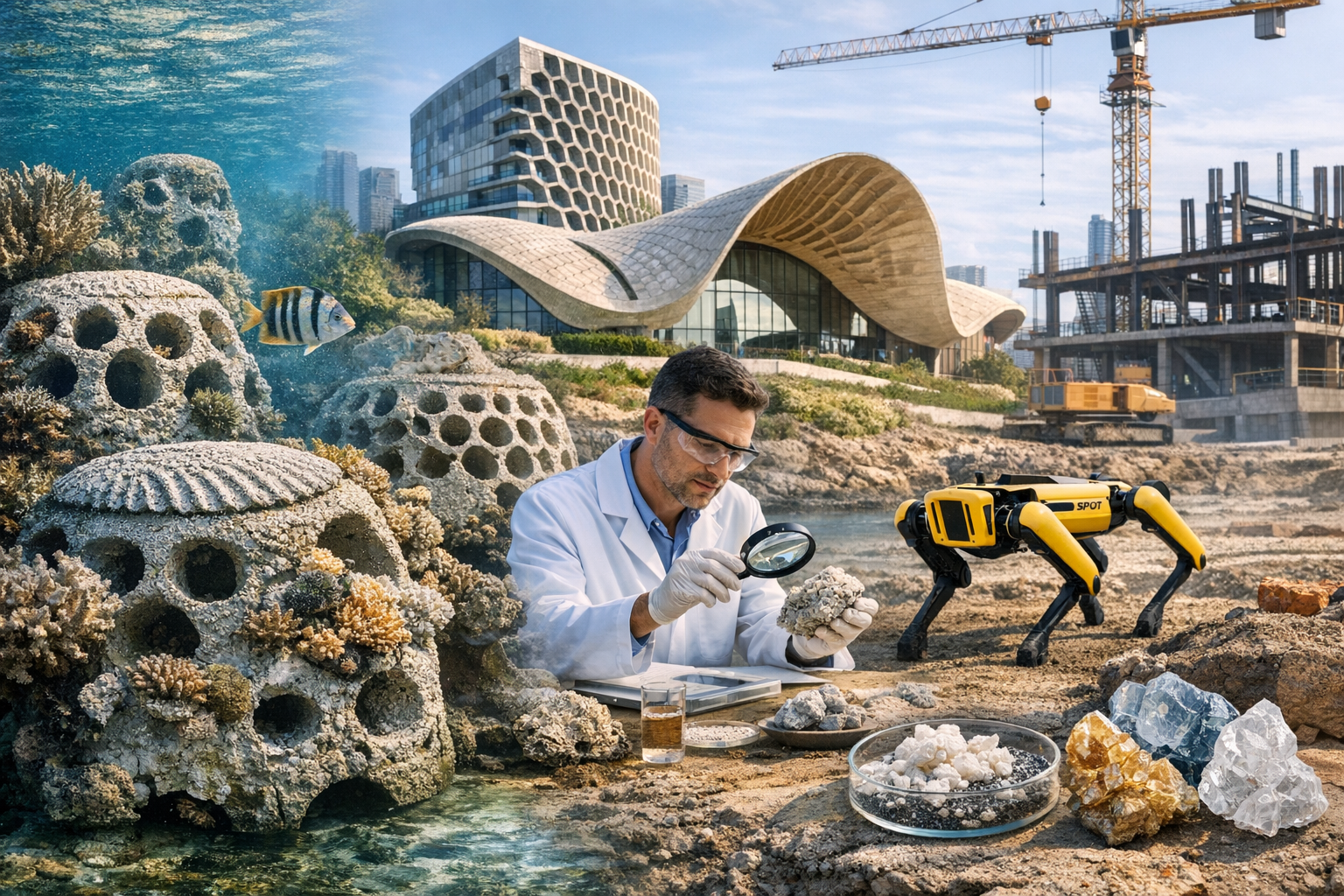

ECOncrete: Concrete that strengthens both structures and marine ecosystems

The Israeli company ECOncrete specializes in concrete for marine infrastructure such as submerged walls, piers, and breakwaters. The concrete is designed to encourage the growth of marine life like corals and algae, which helps rehabilitate damaged ecosystems, improve water quality, and contribute to carbon capture.

ECOncrete’s technology is already in use in ports, parks, and urban projects in the United States, Europe, and Israel, and meets numerous international standards for concrete and green construction. On site, the material functions exactly like conventional concrete, but with added environmental value. In some cases, it even facilitates permitting processes and provides access to tenders that prioritize green projects.

Superwood: Wood stronger than metal, with a low carbon footprint

The American company InventWood is soon expected to begin industrial production of a breakthrough material called Superwood - wood that undergoes a molecular transformation process making it stronger than steel while being six times lighter. Thanks to these properties, Superwood may replace steel beams in building structures and be used in products that require high durability, such as bulletproof and fire-resistant doors. When exposed to extreme heat, the outer layer of the wood chars in a controlled way, preserving the inner part. For the construction world, this presents an opportunity to combine durable and innovative materials with environmental goals, without compromising strength, safety, or cost.

Not just to meet goals - but to benefit from them

Each of the solutions presented here is not just intended to look good in an ESG report, but to provide real advantages on site. Advanced and green materials make it possible to save energy, enhance long-term durability, reduce future maintenance needs, and comply with increasingly strict regulations. The bottom line is that instead of choosing conventional materials and then adding a green layer around them, we can start the other way - with planning and materials that address both environmental and business needs from the very beginning.