Construction 4.0 – II Part New Construction Technologies

Construction 4.0 – II Part

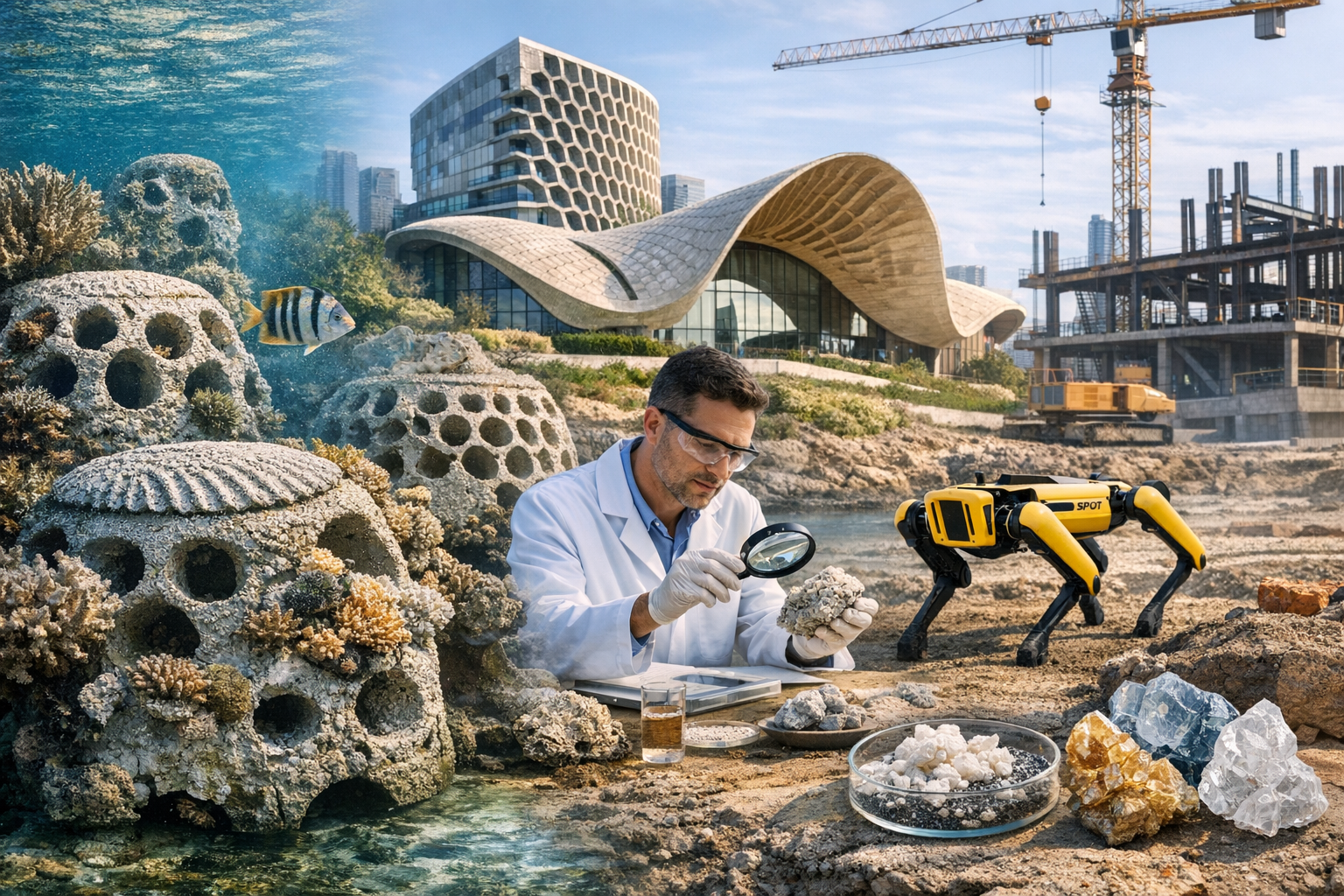

New Construction Technologies

ConTech is the home of novel construction technologies, and is currently working on more than a hundred new technology solutions, many of which have already appeared on the market. These have mostly been tested in the English and American markets. Currently, there are two main areas of technology: Proptech solutions, also known as Property technologies. These innovations are targeting investment development companies.

The other group is Construction Tech, also known as construction Technology. As the Industry 4.0 evolving, industry boundaries are beginning to blur, and the digital world is increasingly moving toward virtual interconnected technologies. The emerging construction solutions are targeting each phase of the construction industry, linking work processes have been separated so far. Three major technological trends were introduced at the conference: Artificial Intelligence, Robots, and 3D Printing.

What are those new technologies? What can we expect?

Design

More than 15 innovations were represented in this topic at the conference, two of which were introduced:

AI based design speeds up execution while increasing the efficiency of the entire project. Swapp’s Artificial Intelligence design based on a variety of scenarios, taking into account the long-term outcome of the changes, providing a flexible solution for both owners and tenants. All you need to do is to upload your existing plans. SWAPP then optimizes designs with a variety of background data, taking into account project requirements, and automatically generates execution plans accordingly.

A BIMMATCH technology brings an innovation to the market that solves not only planning but also procurement and budget issues. Through the company-developed platform, once you upload your BIM model, you can click on a component to select from a number of suppliers and instantly assign the selected product to the appropriate component of the model, so you can quickly and accurately estimate your entire project budget.

Using the power of AI, Firmus helps construction companies learn from their mistakes and identify design and coordination problems. Running 3D plans through the platform allows the user to optimize the plans, highlighting potential risks and errors based on historical project data. The interface collects data from millions of reports using AI, then presents identified errors, costs, and groups the data by complexity. What does this actually mean? The NCR reports and the data generated at site are collected by AI and then traced back to the appropriate location in the BIM model

Execution

Many new solutions are coming to the execution phase as well.

OKIBO's smart robot uses a new 3D scanning method to map its environment in 3D, enabling continuous progress monitoring, BIM model and reality comparison, and a reliable understanding of plastering requirements. Robots equipped with advanced sensors and AI algorithms require minimal human intervention. Thanks to its simple user interface it is easy to set up the robot. Using sophisticated and robust industrial robotic arms, the machine performs high-quality plastering work in a fraction of the time spent on conventional plastering techniques. Automating a large number of construction work helps prevent potential risks for workers, such as working at height or using toxic materials. Because the robot can operate autonomously and continuously, it can operate for a competitive prices for 24 hours a day, consuming only electricity.

CIVDRONE automates the construction marker process. Advances in drone technology have made it possible for the start-up company to automate the layout process with drones throughout the construction site. Smart drones are able to perform day-to-day setting without the need for human resources on the job site. Each smart pile has QR codes, which can be read by any smart device, and stores information in the cloud, providing simple, clear instructions for people on the site.

SAMSON LOGIC linked procurement, organization and logistics. Lean Logistic, with its modular smart containers, offers a new way to handle materials coming to the construction site: the materials you order from the manufacturer are placed in containers with smart labels. Delivering and storing at the construction site allows for continuous inventory management. Special IoT sensors offered by the company increase the safety of crane lifting. Sensors indicate potential hazards to the crane operator. The system can also maximize the crane's lifting capacity - saving time for the crane and workers.

ULTRAWIS aims to increase market efficiency by targeting the tower cranes market. ULTRAWIS aims to become the market leader in the global market with an automatic command and control service for tower cranes.

To me, the technology presented was very impressive. This technology has made it possible for to remotely control of cranes from containers. In addition, the technology provides a real-time 360-degree view of the tower crane from the entire project and integrates the project's BIM model with the system to provide immediate quantitative measurements of, for example, the amount of land extracted.

By using artificial intelligence and deep learning, INTSITE optimizes and automates the use of machines in the workplace. It offers a new opportunity to increase the efficiency of heavy machinery industries in the construction, mining and container industries. Founded in 2017 in Haifa, Israel, INTSITE boasts exceptional algorithm developers, industry professionals and technology experts. Originally developed as a control system and intelligent dashboard for construction cranes, INTSITE technology has been rapidly extended to other industries where experience with sub-optimal heavy machinery poses similar challenges in terms of efficiency and profitability.

INTSITE's patented technology combines algorithms used in Computer Vision, Deep Learning, and the aerospace industry with advanced hardware (camera and other sensors) to turn every heavy machine into a fast and cost-effective intelligent and autonomous robot (machine), increasing security and efficiency. With INTSITE technology, machines are connected to a cloud, connecting them to a huge network in the world, enabling data-driven decisions and real-time monitoring of site activities.

Health and Safety

Construction sites are a work environment that deserves special attention in terms of health and safety.

The Safeguard application is a real-time safety management tool that enables executives, project managers, safety managers, and project team members to reduce risks and maintain construction continuity. Safeguard is an accounting system that stores all critical safety information: safety issues, incident reports and security audits.

As built documentation and inspection

New technologies are coming to support the work for both project managers and jobsite inspectors.

DatuBIM is an automated cloud-based platform designed and built for construction infrastructure projects. This service allows construction companies to monitor project progress, quality assurance and budget control based on analytical data extracted from field data. DatuBIM is integrated into every phase of the project to automate and optimize processes.

LightYX LightYX is a startup with innovative, state-of-the-art technology.

LightYX addresses one of the biggest problems in the construction industry: the gap between office and construction site, which can lead to cost and schedule overruns. The LightYX 3D BIM autonomous projector, allows construction workers to build quickly and properly at first. Using their technology, they project the augmented reality of construction plans, with a laser at the real construction site, to scale, with millimeter accuracy. The LightYX solution is easy for workers to manage with a single click. Their goal is to add immediate value for each role in the value chain of construction work.

For workers, to be able to execute 2D and 3D plans quickly and correctly, for supervisors, to be able to continuously assess the implementation quality fromremote locations. And for companies, to increase their revenues and margins by:

Adopting BIM easily, Reducing working time, Reducing workmanship errors, Allowing workers to do more work in less time while the company could take more projects only by using a "LightYX BeamerOne".

Constru brings advanced AI to the construction industry. Their solution brings state-of-the-art computer visualization to meet and then significantly exceed human capabilities in controlling and analyzing the construction process. The platform assesses the quality of execution, budget and schedule. Constru, thus, reduces project risk, improves efficiency and increases return on investment. The Constru solution consists of three main parts: data collection, where on-site 360° continuous visual data is is captured throughout the project lifecycle. They then use Computer Vision technology to extract the data. The analysis used to provide engineering and business intelligence during data analysis provides a continuous view of the current status of the project.

About the author

I have been working in the construction industry for 8 years. My mission is to generate value for the construction industry through introduction of new technologies. I passionately follow the industry's new digital solutions. In believe, the companies need to prepare with appropriate professional skills and digital technological solutions for the digitalisation of the construction industry. My goal is to facilitate this transformation.

In addition, I am passionately supporting and assisting female workers in the construction industry.

I am curiously looking forward to the new developments in this new industry.

The impact of the pandemic highlights the fact that the construction industry is particularly sensitive to the presence of labour.

The sudden slowdown in work provides a good opportunity to reflect on how well we are working in the construction industry. Now is the time for businesses to rethink where they are headed. Do they want to increase efficiency with the right technology, or increase workforce and get stuck in the past?

Nagy Orsolya

MBA in Business Economics

MSc. Structural Engineer