Meet the Startup: Ception - AI for enhanced operation of heavy machinery

Ception is harnessing precise localization and mapping to enhance industrial mobility's safety and productivity, both in human and autonomous operations

Back in the late 1970s, engineers from Tsukuba University took the first ever autonomous passenger vehicle for a test drive on Japan’s roads. Not to be outdone, in 1986 Mercedes, together with industry and academic stakeholders in Europe, began working on its Eureka Prometheus research project to develop an autonomous collision avoidance system. Fast forward ten years to 1996, and Caterpillar introduced the first ever autonomous haul truck.

30 years later, and the autonomous revolution is still ongoing, and in multiple sectors. However, while it may seem that confined areas such as construction sites and mines would be ideal for this technology, in practice the use of autonomous vehicles in these environments remain low. Currently, only 3% of the haul trucks used in mines worldwide are autonomous, while autonomous equipment used in the construction industry accounts for only 0.1% of the market size.

Despite significant progress in core enabling technologies in recent years, such as advanced sensors, algorithms, and machine learning, numerous barriers remain and impede larger scale autonomous adoption in industrial sites; the high cost of the equipment and the integration projects, safety and regulation related issues, and resistance due to the natural human fear of change.

As the efforts to develop better autonomous systems continue, complementary technologies designed to improve the operator’s safety and productivity are emerging. Yet, the adoption of these assistance systems is also encumbered by challenges of cost, reliability, and accuracy. Too often operators are harassed by false alerts, which hurts productivity and even leads to switching off these systems altogether, rendering them useless. While the autonomous revolution is far from complete, the progress made so far allows us to develop the next generation of assistance and monitoring systems for heavy equipment, thus greatly improving them. These assistance systems provide immediate value in the form of operational optimization without the need to wait for a large-scale integration of autonomous equipment.

Construction applications involve both stationary and mobile heavy machinery, which introduces safety risks due to their size, the operators’ blind areas, interactions between different types of equipment, the layout of the job site, and human error due to monotonous work over long hours. An additional challenge construction companies are facing is productivity. Currently, a foreman’s ability to monitor the overall productivity on the job site in real time and make necessary adjustments is limited and relies on manual measurements and other manual processes. Given the obvious need for optimization, it is no surprise that the smart construction market is growing rapidly; IoT, Digital Twin, and Geo-enabled construction technology markets are estimated to surpass $1 trillion in size by 2025, with a CAGR of about 30%.

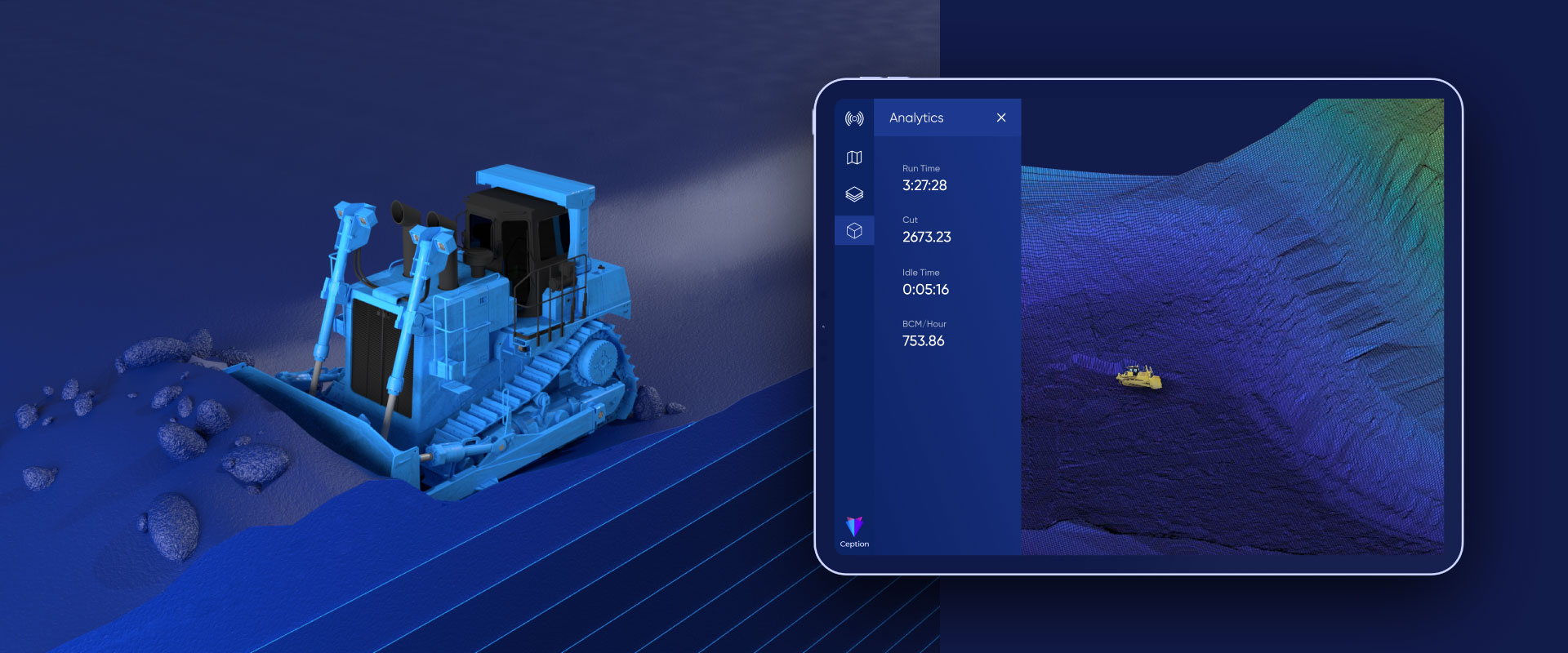

Ception is developing an AI-powered system for mobile heavy equipment based on accurate mapping and localization even when no GPS is available.

By using computer vision technology and deep learning algorithms, the system improves operational safety, productivity, and sustainability. The hardware and software kit is OEM-agnostic and provides operators with real-time alerts and guidance, while collecting data and providing job site related insights to the site managers and foremen. The product can be used for a wide range of applications and use cases: accident prevention,obstacle detection, planning versus execution, volume analysis, performance monitoring, road condition monitoring, and more. In addition to its aftermarket product, Ception also offers an SDK for integrating the localization, mapping and applications layer in autonomous vehicles and other technological systems, thus accelerating the autonomous adoption.

Real-time collision and hazard avoidance system (CXS) to increase operator’s safety. Includes a safety log for foremen and site managers.

Road condition and hazard monitoring, providing foremen and managers with real-time operational status, as well as analytics and insights from the site.

Planning vs. execution: real-time on-going performance monitoring and volume calculation for enhanced operational productivity.

For more details:

Noa Tamir, Business Development

noa.tamir@ception.ai // info@ception.ai

Sources:

[2] driving.ca

[3] www.cat.com

[4] www.mining.com

[5] www.roboticsbusinessreview.com

[6] www.ey.com