Circular Economy in Construction: From Vision to Practice

The construction industry is one of the world’s largest consumers of resources - and one of its biggest waste producers. It is estimated that about 30% of global waste comes from construction and demolition. In Israel, the estimated figures are similar, and the challenge of managing waste, reducing emissions, and using resources more efficiently has become more critical than ever.

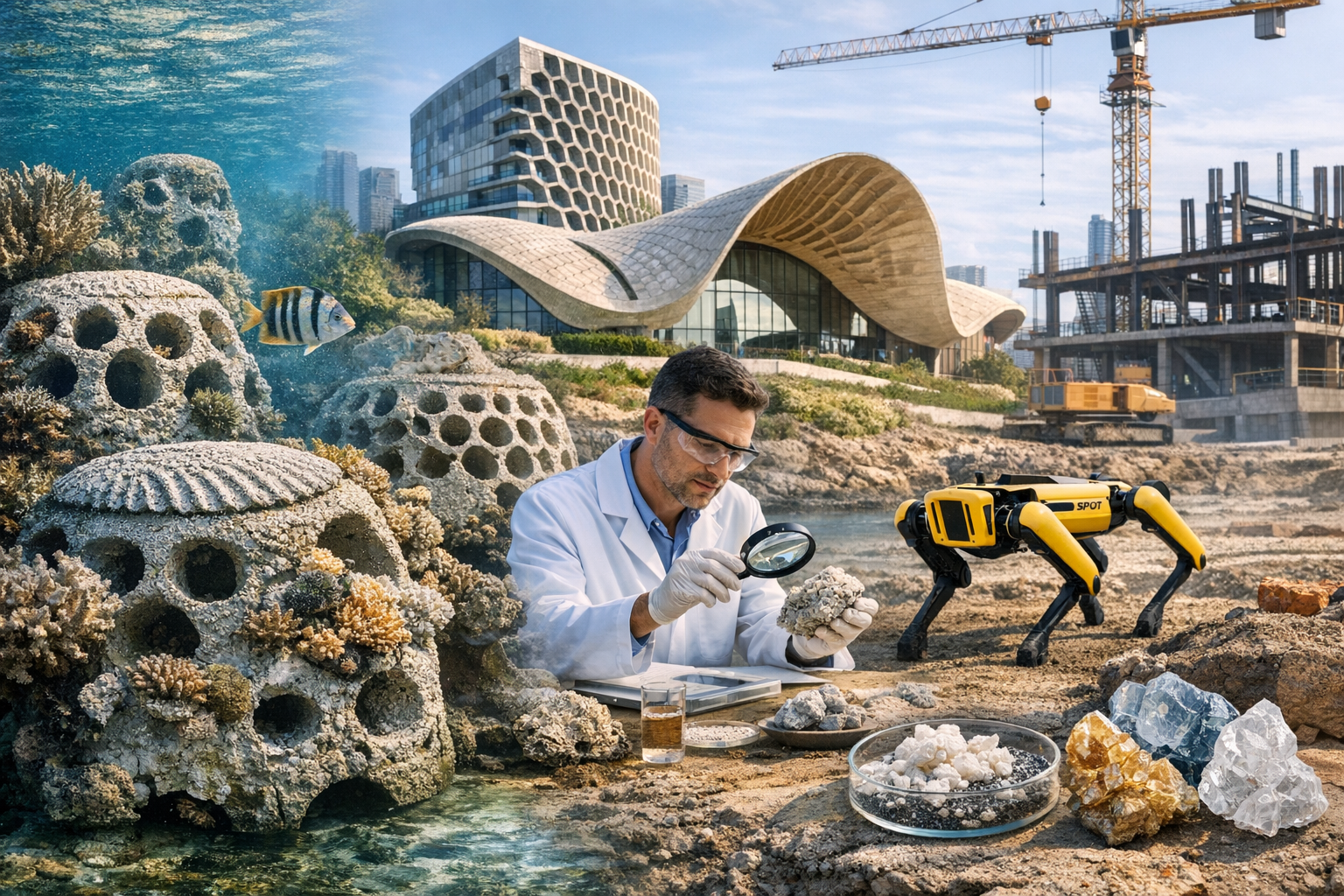

The circular economy offers both a conceptual and practical shift: moving from a linear “produce-build-discard” model to one in which materials re-enter the value chain. Reusing building components, recycling raw materials and construction waste, and shortening supply chains are not just theoretical ideas; they are practical tools already being implemented worldwide, and increasingly also in Israel. Yet, the path toward broad adoption remains full of challenges.

Reuse of Elements from Demolished Structures

Reusing existing components, such as beams, flooring, staircases, windows, and railings, helps reduce the need for new raw materials. In 2022, the Catherine Commons Deconstruction Project at Cornell University demonstrated the environmental benefits of controlled dismantling.

By recycling and reusing materials such as wooden boards removed from floors, walls, and roofs, the project significantly reduced waste and enabled resource reuse compared to traditional demolition. However, this approach requires careful disassembly, inspection, preservation, and reassembly of intact parts, and close collaboration between architects, engineers, and contractors.

Recycling Construction Waste into Raw Materials

Recycling construction and demolition waste is a cornerstone of the circular economy. It transforms what was once an environmental burden into a valuable resource. The process involves crushing old concrete into new aggregates, separating metals (mainly steel and aluminum) for reuse, processing wood into boards or secondary products, and sorting mixed waste to create fill and base materials.

In many countries, a high percentage of recycled materials is fed back into the construction industry, replacing virgin resources. This reduces landfill waste, limits new quarrying, and lowers both logistical and environmental costs.

In Israel, this field is growing rapidly, with dedicated recycling facilities and innovative companies turning local waste into high-quality building materials.

UBQ Materials, a groundbreaking Israeli company, converts mixed waste, including organic materials and hard-to-recycle plastics, into a new, sustainable thermoplastic material. This material can be integrated into existing manufacturing processes and is already being used in the construction sector for a variety of applications: pipes and partitions, cladding panels, interior walls, flooring, and decorative design elements. By incorporating UBQ’s materials into buildings, developers reduce the need for virgin resources, prevent landfill accumulation, and cut emissions, creating both environmental and economic value. The company operates in Israel, the Netherlands, and the United States.

Greenmix, part of the Beni & Tzvika Group, is one of Israel’s leading companies in demolition and construction waste recycling. Active since the 1980s, it was among the first to identify the need for dedicated recycling facilities. Today, the company reports one of the highest recycling rates worldwide, up to 95% of incoming waste, including concrete, metals, and infrastructure materials. The recycled outputs are reintegrated into the construction industry as aggregates for infrastructure, fill, and sub-base layers, as well as in public and private projects. This activity reduces landfill use, minimizes the need for new raw materials, and promotes the principles of the circular economy in Israel’s construction sector.

Shortening Supply Chains

A key principle of the circular economy is geographic proximity between recycled material sources and the construction sites where they are used. When recycling and manufacturing occur near waste sites and target markets, transportation costs drop, emissions decrease, and market response becomes faster and more flexible.

For example, UBQ Materials’ production facility in the Negev is located near the Dudaim waste site, enabling efficient local waste processing and turning it into readily available raw materials for the industry. Similarly, the company’s new facility in the Netherlands serves the European market, demonstrating how regional deployment shortens supply chains and reduces long-distance transportation dependency.

Implementation Challenges in Israel

To turn these models into widespread reality, several key challenges must be addressed:

Standards and Regulation

Israeli building standards often focus on conventional materials. Introducing recycled or alternative materials requires reevaluation of standards and complex approval processes.

Initial Investment Costs

Establishing recycling plants, purchasing equipment, and installing cleaning and sorting systems demand substantial upfront investment, especially in the early stages.

An Underdeveloped Market

Even when high-quality recycled materials are available, without consistent demand or willingness to pay slightly higher prices initially, such models struggle to achieve long-term sustainability.

Looking Ahead

Circular economy in construction is no longer a futuristic vision; it is a rapidly growing global trend. Israel has made meaningful progress, from innovative company initiatives to the establishment of dedicated recycling facilities, yet large-scale adoption is still ahead. Achieving it will require collaboration between government, contractors, and innovation-driven companies to create incentives, standards, and sustainable business models.

The shift from “build and discard” to “build and reuse” is not only an environmental necessity but also a business and economic opportunity. Those who adopt circular economy principles effectively will gain a clear competitive edge, lower long-term costs, and contribute to a greener, safer built environment for generations to come.