Off-Site Construction: Israel’s Solution to Workforce, Costs, and Timeline Challenges

Israel’s construction industry faces growing challenges: the cost of materials and labor continues to rise, project timelines are stretching longer, and a severe shortage of skilled workers is undermining both quality and construction pace. In this reality, traditional methods are no longer enough. Off-site construction, including modular and industrialized building, is emerging not only as an innovative alternative but as a vital necessity. In this article, we explore how modular and industrialized methods shorten project phases, improve building quality, and offer a smarter substitute for conventional construction.

A Shift in Mindset: From the Site to the Factory

While traditional construction happens almost entirely on-site, exposed to weather, labor availability, and logistical constraints, industrialized construction moves a large part of the process into a controlled environment: the factory. There, building components such as walls, ceilings, and even complete rooms are produced under strict quality control, with efficient use of materials and full coordination between electrical, plumbing, insulation, and finishing systems.

When these components reach the site, assembly is faster, cleaner, and more precise than in conventional building. According to a 2025 McKinsey report, modular construction can reduce on-site labor needs by up to 40%, shorten project timelines by up to 50%, enable cost savings (when applied at scale and correctly managed), and significantly reduce carbon emissions.

Precise Planning and Consistent Quality

One of the key advantages of off-site construction is consistency. Manufacturing under controlled conditions ensures a uniform, high standard that doesn’t depend on the varying skill levels of on-site crews. Components are fabricated based on precise plans, often using Building Information Modeling (BIM), which guarantees full integration between elements starting in the design stage.

The result is a dramatic reduction in errors and rework on-site, issues that typically account for a large portion of project delays and budget overruns.

A Major Advantage in Execution Time

Industrialized and modular construction allows parallel workstreams: while foundations and exteriors are being built on-site, interior components are produced in the factory. This dual-track process can cut months from project timelines, a critical factor in public, institutional, and rental housing projects, where every delay carries an immediate financial cost.

In Israel, where the housing shortage is deepening, the meaning is clear: more housing units in less time, with less dependence on foreign labor.

Addressing the Workforce Shortage

The shortage of skilled labor is one of the biggest obstacles facing Israel’s construction sector. In a factory setting, however, fewer workers are needed, mainly technicians, engineers, and machine operators, not hundreds of field laborers.

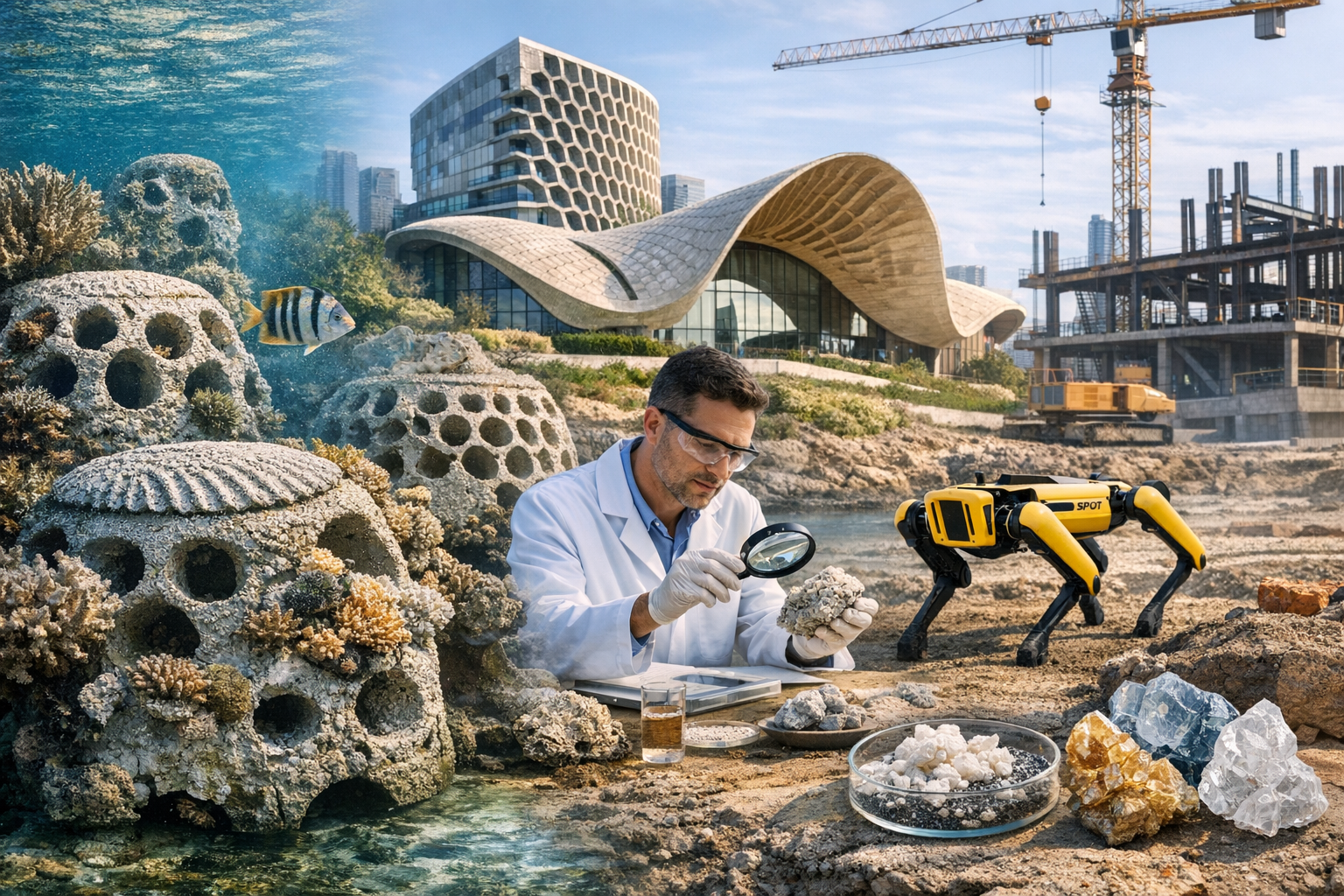

Industrialized construction thus offers a strategic opportunity to address the workforce crisis: it reduces reliance on foreign labor, enhances safety (especially at heights), and enables the integration of automation, robotics, and artificial intelligence into production processes.

Advancing Sustainability

The move to off-site construction isn’t just about efficiency; it’s also about sustainability. A controlled manufacturing environment enables more accurate use of materials, less waste and emissions, and optimal energy consumption. In addition, faster on-site assembly means less noise, dust, and heavy transport, improving the quality of life for surrounding communities.

The Israeli Landscape

In recent years, Israel has seen growing adoption of industrialized methods. Construction companies and startups are developing modular solutions and integrating them into both public and private projects, from schools and daycare centers completed in just a few months to residential towers assembled from pre-produced sections.

For example, in the Etrog Project in Ashdod, Tidhar is constructing a six-story building in which only the parking level, ground floor, and elevator core are built conventionally. All 75 residential units are produced in full at Tidhar Modular’s factory in Yavne and assembled on-site.

Looking Ahead: A Revolution Built in the Factory

Once considered a temporary or “light” solution, industrialized construction today represents a complete engineering approach, precise, durable, and long-lasting. With growing demand for fast, high-quality housing, Israel is well-positioned to lead in modular construction, thanks to its technological innovation, engineering expertise, and strong entrepreneurial ecosystem.

Government support and regulatory initiatives can accelerate adoption through updated standards, incentives for innovation, and the integration of digital tools for planning and supervision.

From Challenge to Solution

Off-site construction holds enormous potential to transform Israel’s construction industry. It is faster, more accurate, more cost-effective, and safer. Beyond improving productivity and timelines, it provides a solution to the skilled-labor shortage and redefines the quality of Israeli construction, shifting it from the dusty, labor-intensive worksite to the precise, technology-driven production line.