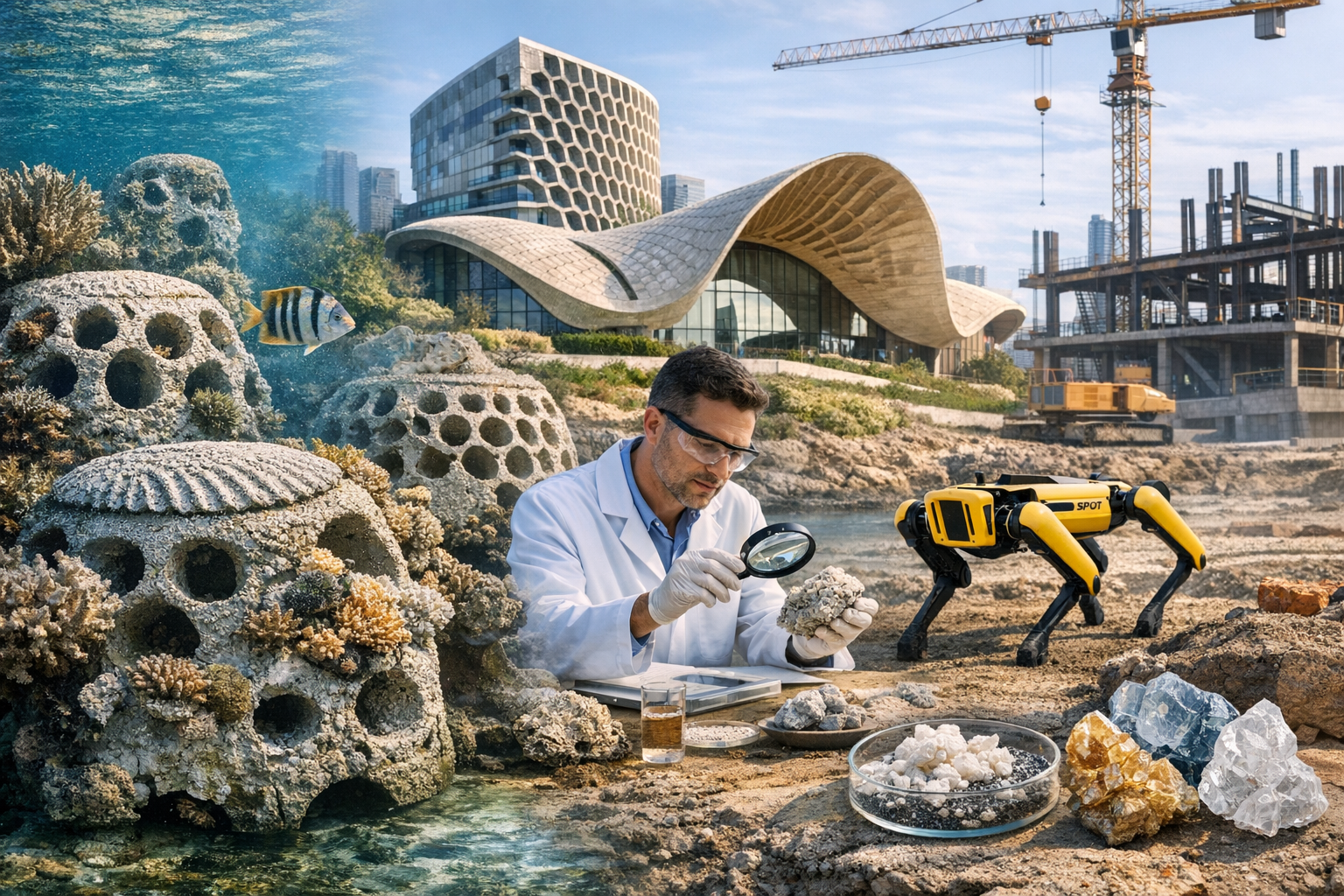

Concrete Substitutes: Today’s Innovation and the Opportunities Ahead

Concrete is the world’s most widely used building material, but comes with a heavy environmental cost. The concrete industry is responsible for about 8% of global carbon emissions, mainly due to the cement production process, which requires extremely high temperatures and enormous amounts of energy. Added to that are the intensive mining operations for sand, limestone, and other raw materials.

In recent years, a global movement has emerged to develop substitutes and additives that reduce dependence on traditional concrete. Israel, too, is seeing growing research and entrepreneurial activity in this field, yet the road from laboratory innovation to widespread adoption on construction sites is still long.

Global Trends in Concrete Substitutes

Around the world, several promising technologies are emerging:

Self-healing biological concrete

One of the most fascinating technologies already available incorporates bacteria into the concrete mix. When cracks form and water seeps in, the bacteria “wake up” and produce calcite that seals the crack, effectively allowing the concrete to heal itself.

Limestone Calcined Clay Cement (LC3)

This technology combines calcined clay and limestone and can reduce emissions by up to 40% compared to traditional Portland cement, while maintaining the same mechanical properties.

Flexible concrete (ECC)

Engineered Cementitious Composites (ECCs) are mixes contain ultra-thin synthetic fibers that allow the material to bend and absorb stress without crumbling. It’s particularly suitable for earthquake-prone regions.

Mycelium-based insulation materials

Companies worldwide are already producing insulation boards made from mycelium (the root structure of fungi) and agricultural waste. These materials provide excellent thermal and acoustic insulation while dramatically lowering carbon footprint.

Recycled aggregates

Crushed glass, recycled plastic, construction waste, sugarcane ash, bamboo fibers, and rice husks are all being used as substitutes for traditional gravel.

What’s Already Happening in Israel?

Israel demonstrates impressive entrepreneurial and academic activity in this field, although most projects are still in early stages of development and implementation.

ECOncrete is Israel’s leading success story in the field. Founded by Dr. Ido Sella and the late Dr. Shimrit Perkol-Finkel, the company developed an ecological concrete that is non-toxic to marine life and promotes natural biological colonization by marine organisms. The technology has already been implemented in dozens of projects worldwide, in ports, piers, breakwaters, and marine infrastructures in New York, San Francisco, and beyond. It is one of the few Israeli innovations that has successfully made the leap from research to large-scale commercial application.

Starstone is another Israeli company pioneering a biological approach to cement and concrete production. Using bacteria and fermentation processes,

Starstone aims to revolutionize cement manufacturing and reduce carbon emissions. Based on natural biological mechanisms, its solution provides an eco-friendly and cost-effective alternative that performs just like traditional concrete. The company is currently in advanced development stages.

In addition, Ben-Gurion University researchers are studying the use of coal ash and industrial by-products as partial substitutes for cement.

The Gaps: What’s Preventing Wider Adoption in Israel?

Despite the impressive potential of innovative concrete substitutes developed in Israel and around the world, widespread adoption still faces several major obstacles:

Regulation and standards

Israeli construction standards are based on traditional materials such as Portland cement, gravel, and sand. Introducing new materials requires certifications, structural testing, and revisions to local standards, an expensive process that can take years. Israel’s climate (sun exposure, humidity, and temperature fluctuations) also requires local testing, even for materials with international certifications.

Industry conservatism and lack of awareness

Contractors, engineers, and concrete plants are accustomed to familiar and proven systems. Adopting new materials requires retraining and adjustments, and often involves fear of the unknown.

Cost and market readiness

Advanced substitutes are sometimes more expensive due to R&D costs and unique production processes. Production infrastructure and supply chains can also impact pricing. To compete with traditional materials, new alternatives must show clear advantages, such as energy efficiency, durability, and low maintenance. However, construction companies often focus on short-term costs, while long-term savings benefit the building owners and are not always considered during construction.

Lack of long-term performance data

Concrete structures are designed to last for decades, but there is still uncertainty about the long-term performance of new materials. Builders want to see how these materials behave over time under conditions like corrosion, temperature variation, explosion, or humidity. Without extensive long-term data, adoption remains slow.

Design complexity

Building with biological or bio-based materials requires an interdisciplinary approach involving architects, engineers, ecologists, and other experts, which can make planning more complex and time-consuming.

What Will Drive Progress?

To bridge the gap between innovation and implementation in Israel, combined efforts are needed:

Economic incentives: Grants and tax benefits to bridge initial cost gaps, especially in public projects.

National pilot projects: Using public construction as testing grounds while collecting long-term performance data to validate material reliability.

Regulatory adaptation: Streamlined approval processes for new materials while maintaining safety standards.

Local supply chains: Encouraging domestic production of materials from biological or industrial by-products.

Education and awareness: Training a new generation of engineers, architects, and contractors familiar with concrete substitutes and their applications.

The future of construction in Israel and worldwide is green, innovative, and full of opportunity. With the right steps, concrete substitutes and bio-based materials can gradually become mainstream, leading the industry toward a more sustainable, resilient, and environmentally responsible future.