Hannover Messe- top automation and industry 4.0 trends to enter construction tech

Construction-tech and industry 4.0

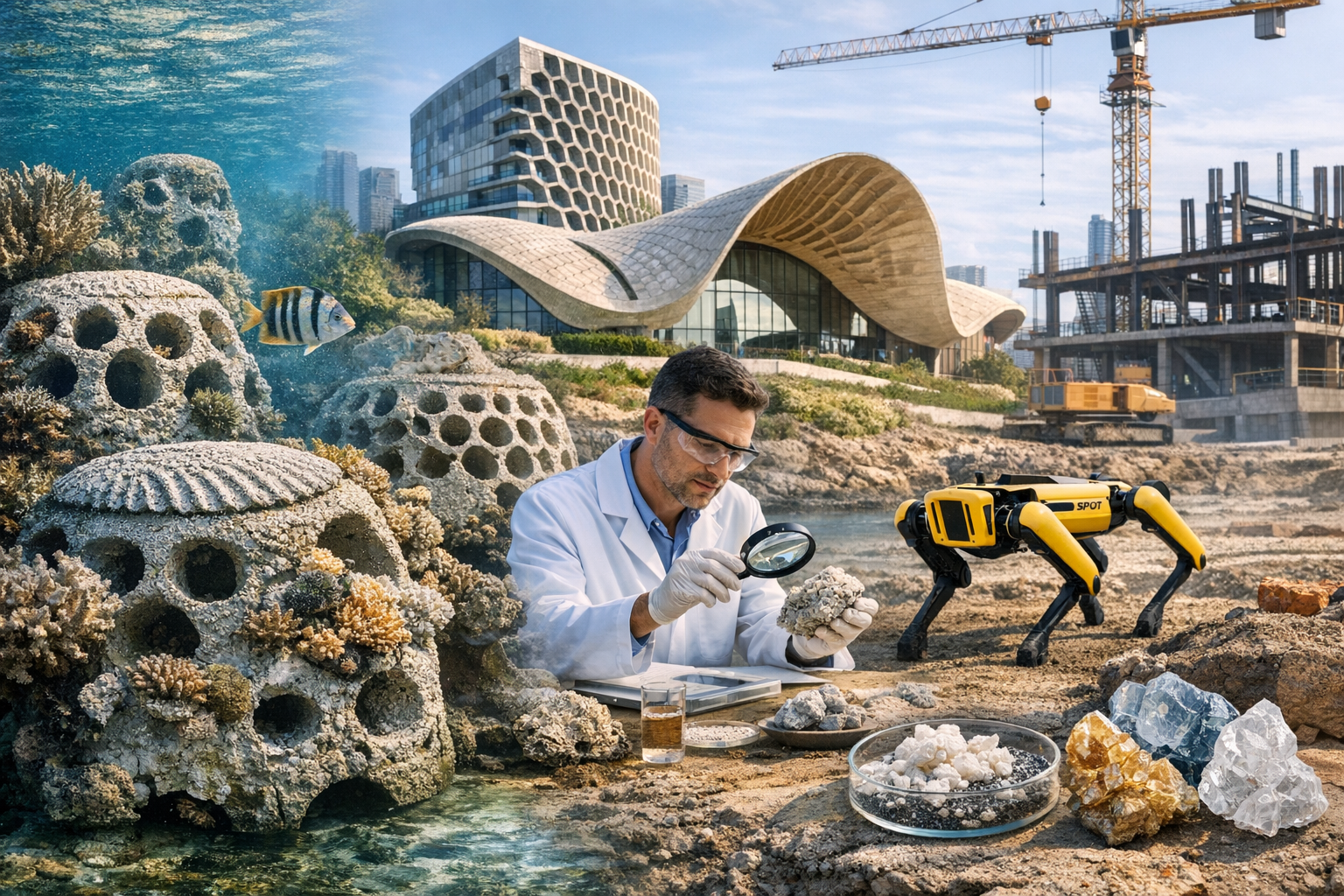

How can we transform the building site from a traditional manual labor process into a modern automated factory? This question has been troubling planners and builders since the early days of industrialization and continues to this day. Attempts at creating modular building factories have only been partially successful due to the many restraints attached, while using advanced manufacturing technologies proves to be too expensive for large scale projects.

However, new technologies revolutionizing the manufacturing world could now be adapted to construction and change the industry from traditional to high tech. Studies have shown that the construction sector is lagging about 20 years behind advanced manufacturing. Why this is happening has many reasons which have to do with customization and scale issues.

Here is a breakdown of five technologies revolutionizing the factory that can soon find their way to a construction site near you.

6 axis robotic arms-

These multipurpose mega claws have the ability to move in almost unlimited paths, giving complete flexibility to create complex maneuvers with payloads of up to 1,000 Kilos.

Famed by the automotive industry, these robotic arms can take up multiple functions by applying different hardware to the tip of the arm. Some common applications include: drills, specialized grippers, air paint, welding, screwing and many more.

Combine those mechanical abilities with AI and computer vision, and you have in your hands almost unlimited power to create the workforce of tomorrow.

Their applications in construction have not yet been proven to be effective as in other fields, However, many applications are being developed these days by startups and academy, producing interesting artifacts, some of which include 3D printing of concrete, wall finishes, weaving, routing and many more.

Cobots-

Mainly used for small scale manufacturing, these robots are meant to work alongside humans and increase manual productivity. These small robots can be very efficient when using smart algorithms and can move very fast and precise.

Their compact size and low payloads make them ideal for working in the human environment without the risks associated with working alongside large machines. Applications range from pick and placement and sorting of objects to sewing and screwing small devices.

For construction, cobots can be used for welding of small elements ,painting, screwing and more. Their main limitation is their size, as so far, the large robots are unsuitable for human contact for safety reasons. However, this can change with the development of enhanced AI control software. Another limiting factor is the rough conditions and many variables of the building site. It will probably take some time before we see robots co-working on the construction site, but it is surely something worth waiting for.

Augmented and virtual reality –

We’ve all had the dream of walking to an empty site, putting on magic glasses and seeing the building come to life. With new augmented reality helmets, it seems like this vision will soon be a reality and will blur the boundaries between the real and the virtual.

Thanks to advance on site GPS integration, Applications are already being developed for on-site augmentation, allowing builders to rapidly compare between the built environment and the digital twin. Other applications include: real time 3D augmented instructions for manual assemblers and AI embedded clash detection.

VR has also shown some impressive improvements with the precision of hand recognition, which allows a seamless integration of hands inside the virtual environment. At the moment, typical use cases of VR is in Intuitive 3D cad modeling as well as in handwork simulation and training.

Metal 3D printing-

3D printing has long been on the map of the manufacturing world as the golden child meant to free it from modular molds and allow freeform design. It’s potential of mass-customization and unrestrained design has benefits ranging from weight optimization to aerodynamic design. For structural purposes, it seems that metal printing shows the biggest promise for matching engineering standards. For this reason, metal printing is seeing a great boom in recent years for the automotive and aerospace industries in order to reduce component weight. Yes, it’s still a niche market and the prices are far from feasible for any mainstream application, but the same has been said about the radio, the car and the tv. With great efforts and funds being poured into its development, perhaps we can see this technology crawl its way into the construction sector sooner than later for unique details and freeform designs.

Advanced BIM design- From planes to buildings

One of the biggest drawback of standard BIM packages is that they provide an ‘out of the box solution’ and very hard to customize for non-standard design. Contrary to mechanical product design which provides a complete 3D model to the screw level, BIM for construction often provides a ‘bird’s eye view’ of the building, calling for later detailing and pricing which is done manually by a third-party.

This becomes even more evident when designing many unique components that require individual adjustments for manufacturing.

Normally used for automotive and aerospace design engineering for complex assemblies, Dessault’s Catia is making a step into the construction sector after being adopted by ‘starchitects’ like Frank Gehry and the likes for high profile projects. The complications of the software meant it required specialists to run it, making it unfeasible for mainstream planners.

With a new interface and simplified workflows, Dassault is hoping to get its generative design tool to be a part of the architect and engineers toolbox.

What’s next?

Will the construction worker of tomorrow be wearing a VR helmet while assisted by AI driven robots? Will there even be a construction worker on the new building site? Naturally, it will take some more time for these technologies to penetrate the construction site, but some developments are already taking place, providing study cases that could perhaps be the standard of tomorrow.